Methods Machine Tools, Inc.

1 / 10

Located in Memphis, TN, the Methods Technical Center offers hands-on machine demonstrations, engineering support, and training services. Connect with our local team for expert machining solutions and technical guidance.

2 / 10

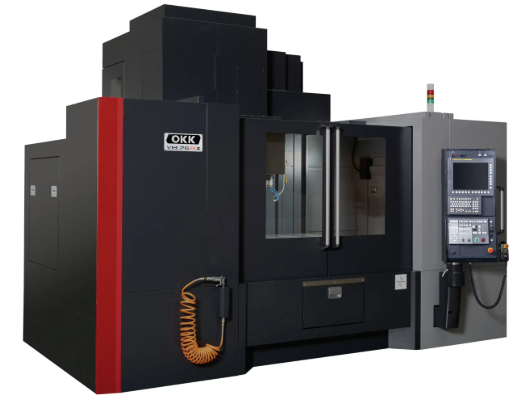

The OKK VM76RII delivers high cutting performance with increased rigidity and precision. Featuring box-way feed axes and a robust frame, it’s ideal for machining tough materials like titanium—engineered for heavy-duty cuts and ergonomic operator access.

3 / 10

The Nakamura-Tome NTY3-100V is a high-speed multitasking turning center with three Y-axis turrets and twin spindles. Designed for ultra-fast production, it features ChronoCut software, high-speed indexing, and simultaneous multi-axis machining for reduced cycle times.

4 / 10

The Methods Job Shop Cell Collaborative is a flexible automation system designed for easy part loading and unloading. Ideal for shops new to robotics, it delivers efficient CNC automation without requiring major investments or machine replacements.

5 / 10

The Yasda H-40i 5-Axis Machining Center offers high rigidity and accuracy for both indexing and simultaneous 5-axis work. With options for up to 24 pallets, it supports extended automated production and reduced setup times for cost-effective operations.

6 / 10

The Nakamura-Tome MX-100 RTS combines the versatility of a machining center and a turning center in one compact platform. Equipped with advanced software and up to 96 tools, it delivers high-precision, high-productivity performance across a range of industries.

7 / 10

The OKK VC-X500 5-axis machining center offers ultra-precise process integration with reduced setups and shorter lead times. Featuring a 60-tool magazine and compact design, it’s ideal for automation-ready, high-accuracy part production.

8 / 10

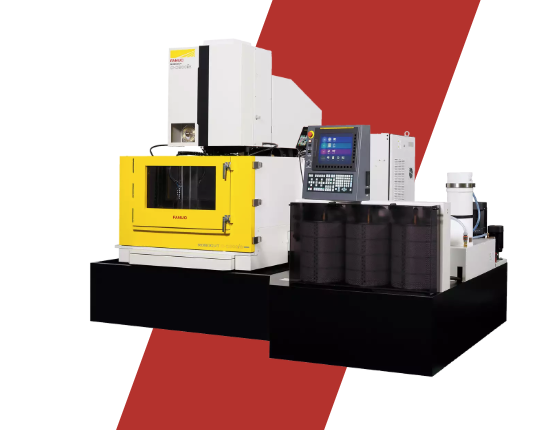

The FANUC RoboCut C800iB-20 Wire EDM offers ultra-precise cutting with minimal re-cast, featuring the advanced 31i-WB control, AWF3 auto-threading, and energy-saving economy mode—engineered in Japan for unmatched reliability.

9 / 10

The OKK HM-X6000 is a high-power 50 taper horizontal machining center built for tough materials like titanium. With core-chilled, dual-anchored ball screws and linear cross roller guides, it delivers unmatched rigidity and precision for long machining cycles.

10 / 10

The Yasda PX30i 5-Axis Machining Center delivers unmatched precision in complex part machining, with high rigidity for hard materials like titanium and inconel. Engineered for automation and productivity, it’s ideal for OEMs and advanced machine shops.