Methods Machine Tools, Inc.

1 / 10

Located in Gilberts, IL, this Methods Machine Tools facility provides local sales, service, and support for advanced machining solutions. Visit us for expert application engineering, machine demos, and personalized consultation.

2 / 10

The Methods MV 1100H is a robust 3-axis vertical machining center built to strict specifications for long-term reliability, precision, and performance, ideal for shops seeking quality results at a competitive price.

3 / 10

The FANUC RoboDrill PC2 System delivers unmatched reliability and speed for milling, drilling, and tapping. With the factory-installed pallet changer and 31i-B5 PLUS control, it enables high-efficiency, unmanned machining across any shop floor.

4 / 10

The Kiwa KH-4500kai is a high-performance horizontal machining center offering one of the largest work envelopes in its class. With fast 1G axis acceleration, a rigid stepped casting design, and field-expandable APC and ATC, it’s built for scalability and speed.

5 / 10

The Nakamura-Tome AS-200LMY-S Sub Spindle RTS features a long bed, powerful milling drive, and 82mm stroke Y-axis for precision multitasking. Designed to eliminate secondary operations, it offers efficient turning, drilling, and milling in one setup.

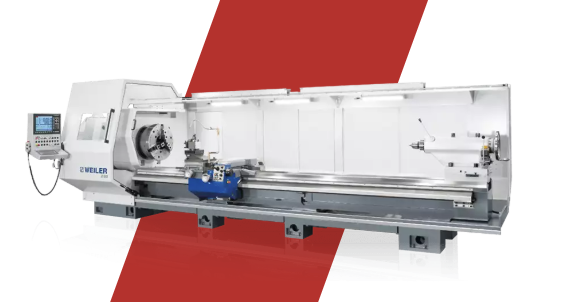

6 / 10

The Weiler E-120 delivers high-efficiency turning with intuitive cycle programming and robust construction. Built for one-off and small batch production, it offers fast setup, ease of use, and consistent accuracy through WEILER’s conversational control.

7 / 10

The Yasda YBM Vi40 is a high-precision 5-axis machining center built for die and mold making. With exceptional rigidity and accuracy, it excels at machining complex geometries in hard materials that challenge traditional 3-axis machines.

8 / 10

The FANUC RoboCut C600iC Wire EDM offers precise cutting with enhanced AWF3 threading for up to 16" thickness. Featuring energy-saving economy mode and 31i-WB control, this Japan-built machine delivers accuracy, reliability, and minimal re-cast.

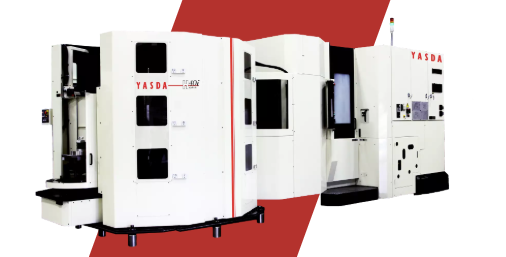

9 / 10

The Yasda H-40i 5-Axis Machining Center offers high rigidity and accuracy for both indexing and simultaneous 5-axis work. With options for up to 24 pallets, it supports extended automated production and reduced setup times for cost-effective operations.

10 / 10

The OKK HM-X6000 is a high-power 50 taper horizontal machining center built for tough materials like titanium. With core-chilled, dual-anchored ball screws and linear cross roller guides, it delivers unmatched rigidity and precision for long machining cycles.