Methods Machine Tools, Inc.

1 / 10

Modern exterior of the Methods Machine Tools headquarters in Acton, Massachusetts, featuring sleek metal siding, large glass windows, and landscaped accents.

2 / 10

Inside the Methods Machine Tools Acton, MA facility, showcasing a clean, state-of-the-art environment with CNC machines from Yasda and Nakamura-Tome.

3 / 10

The Methods Plus-E Automation System integrates with the Fanuc RoboDrill, using a vertical pallet elevator for efficient, space-saving part loading and unloading.

4 / 10

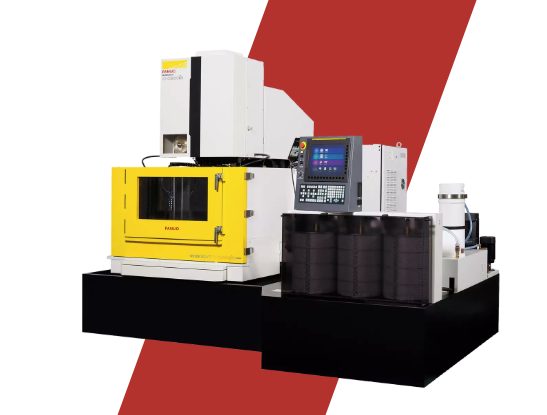

The FANUC RoboCut C800iB-20 Wire EDM delivers ultra-precise cutting with enhanced threading, energy efficiency, and the reliable FANUC 31i-WB control system.

5 / 10

The KIWA KH-4200kai is a compact horizontal machining center with rotary B-axis and factory pallet automation, ideal for high-volume, space-conscious production.

6 / 10

The Nakamura-Tome WY-100V is a twin-spindle multitasking lathe with dual Y-axis turrets, designed for high-efficiency operations like pinch milling and ChronoCut processing.

7 / 10

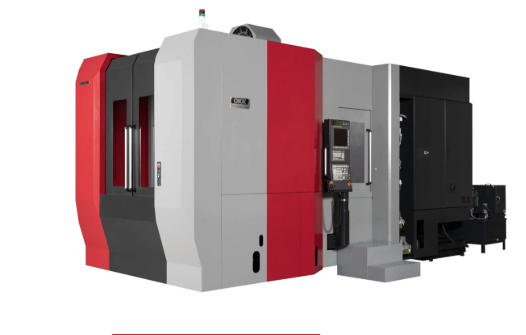

The OKK HM-X6100 is a high-power horizontal machining center engineered for cutting exotic materials with exceptional rigidity, precision, and thermal stability.

8 / 10

The YASDA YBM 7T is a precision machining center renowned for its exceptional accuracy in CNC turn boring applications across high-tolerance industries.

9 / 10

The Nakamura-Tome WT-150II is a dual-turret, multi-tasking turning center ideal for high-precision part families in medical, electronics, and aerospace sectors.

10 / 10

The Methods Plus-K60 Automation System for FANUC RoboDrill enables fast, flexible part and tool changes using a compact rotary storage carousel and robotic handling.