Methods Machine Tools, Inc.

1 / 10

Exterior of the Methods Machine Tools facility in Charlotte, North Carolina with a long brick façade, modern entry column, and a spacious, well-maintained parking area.

2 / 10

Inside the Methods Machine Tools Charlotte, NC facility, featuring the MV 600H machining center in a modern and organized workspace.

3 / 10

The YASDA YBM 9150V is a precision CNC jig borer and vertical machining center engineered for high-speed, high-accuracy machining of large mold bases and die sets.

4 / 10

The Nakamura-Tome SC-300II is a heavy-duty CNC turning center with a 30 HP spindle and slant-bed design, built for high-speed, high-torque precision machining.

5 / 10

The Methods Plus-K MAX Automation System enhances the FANUC RoboDrill with a compact rotary carousel that automates both part and tool handling for seamless changeovers.

6 / 10

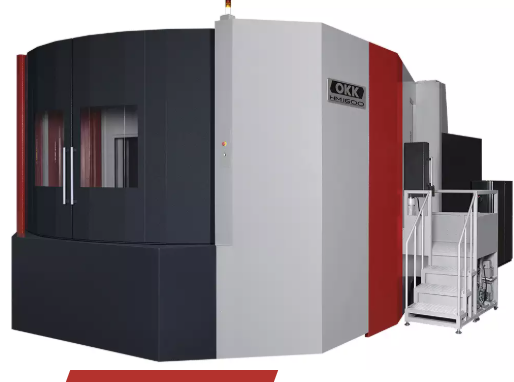

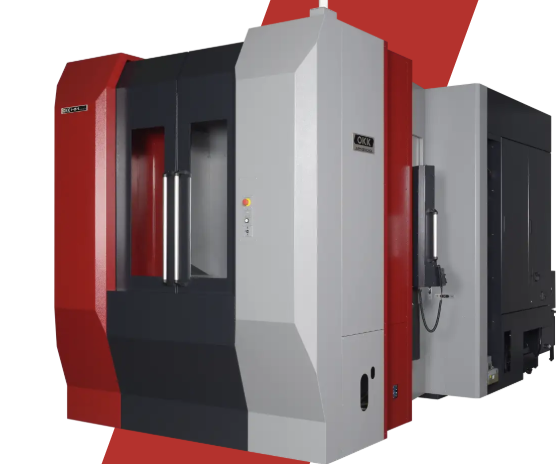

The OKK HM1600 is a high-speed, heavy-duty horizontal machining center designed for unmatched power, rigidity, and efficiency in large-part CNC operations.

7 / 10

The Nakamura-Tome JX-250 is a compact, high-rigidity multitasking machine featuring the NT Smart Cube spindle and twin Y-axis turrets for complex, high-precision machining.

8 / 10

The YASDA YBM Vi40 is a precision 5-axis machining center built for die and mold applications, excelling in complex shapes and ultra-hard materials.

9 / 10

The OKK VC-X500L is a compact, high-accessibility 5-axis machining center designed for reduced setups and large part machining with integrated automation support.

10 / 10

The OKK HM8000S is a high-speed horizontal machining center built for heavy-duty cutting, featuring a rigid box frame and smooth synchronized APC and ATC systems.